High Speed PE Carbon Spiral Pipe Making Machine PVC PE Corrugated Pipe Extrusion Line Plastic Manufacturing

Video

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for High Speed PE Carbon Spiral Pipe Making Machine PVC PE Corrugated Pipe Extrusion Line Plastic Manufacturing, We consider you will be contented with our fair rate, good quality items and fast delivery. We sincerely hope you can give us an option to serve you and be your ideal partner!

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for HDPE Corrugated Pipe Making Machine, PE Carbon Spiral Pipe Extruder Machine, Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

|

Model |

Pipe Diameter(mm) |

Production Speed(m/min) |

Production Capacity(kg/h) |

Total Power(kw) |

|

SJ45/33 |

10~32 |

6~8 |

40 |

20 |

|

SJ45/33 |

25~50 |

6~8 |

70 |

30 |

|

SJ55/33 |

25-63 |

5-6 |

80 |

45 |

|

SJ65/33 |

25-110 |

4-5 |

120 |

60 |

Technical parameter:

|

NO. |

Name |

Quantity |

|

1 |

Single screw extruder with automatic loading device |

1set |

|

2 |

Mould |

1set |

|

3 |

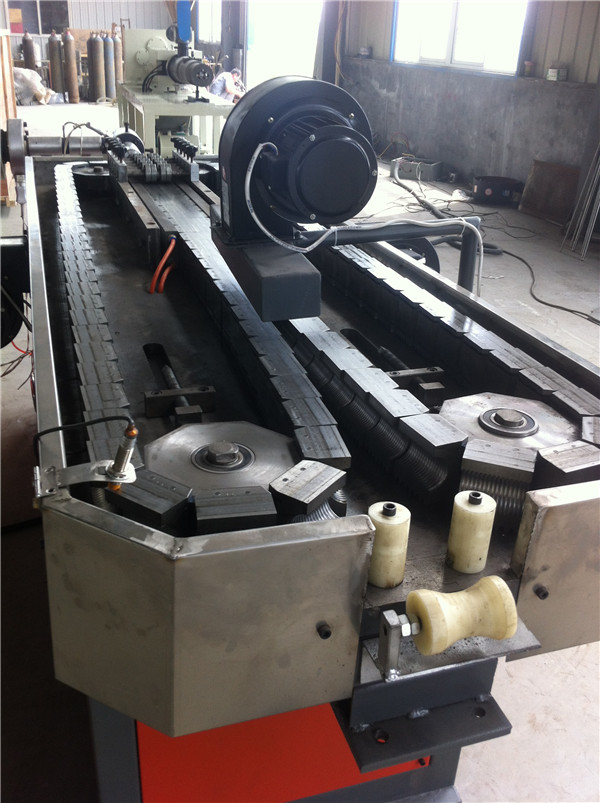

Corrugated forming machine |

1set |

|

4 |

Chipless cutting machine |

1set |

|

5 |

Two stations winding machine |

1set |

|

6 |

Perforator |

1set |

Details Images

1.PE corrugated pipe making machine:Single screw extruder

(with automatic feeding system)

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider (6) Heating method: Cast aluminum heating

(7) Material of screw and barrel: 38CrMoAlA.

2.PE corrugated pipe making machine:Mold

(1) Material: 40GR

(2) Size: Customized

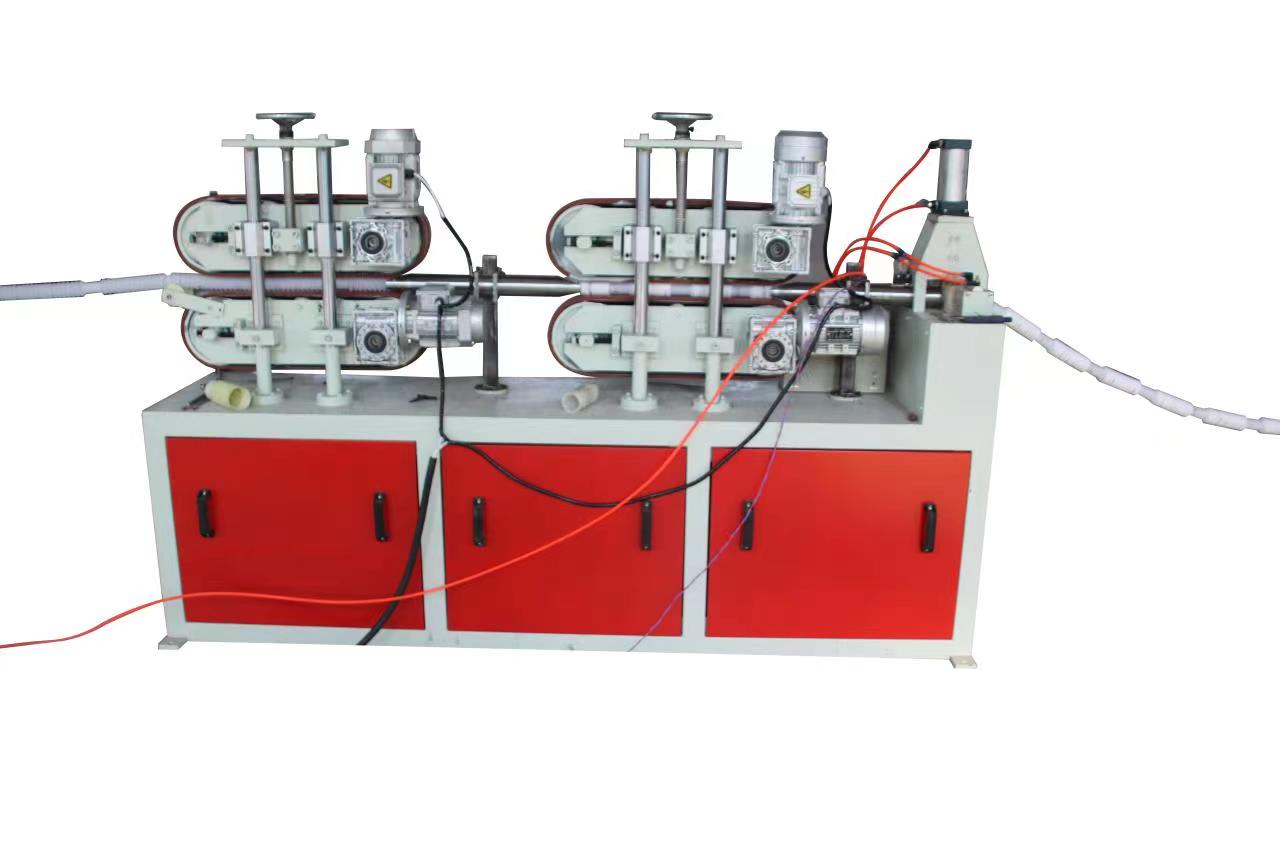

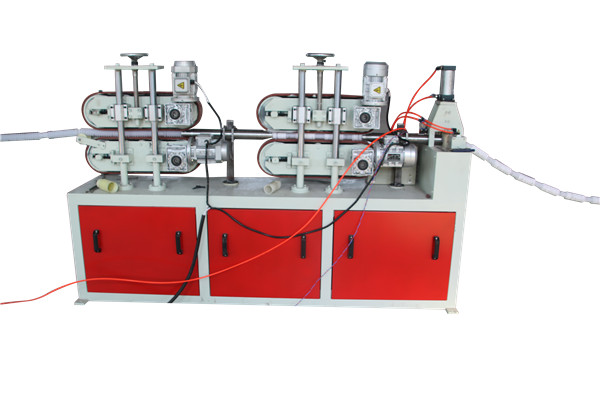

3.PE corrugated pipe making machine:Forming machine

The corrugated formig device can calibrate and cool the pipe from the mould.

(1) Structure Horizontal.

(2) Guide track material is 40Cr.

(3) Block seat material is 40Cr, nitrided.

(4) AC motor: 2.2KW x 1 set.

(5) Blocks is cooled by air cooling fan.

4.PE corrugated pipe making machine:Cutting machine

(1) Motor power: 3 kw

(2) Method: Saw cutting

(3) Cutting scope: Customized

5.PE corrugated pipe making machine:Two stations winding machine

It uses the delicate and exact meter counting and code setting unit made in Korea.

(1) Two stations automatic winding unit without stopping.

(2) Torque Motor:4-6N/M or customizable.

Final product:

After-sale service

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).