Plastic HDPE PE PP MPP Electricity Conduit Water Supply Hose Pipe Tube Extruder Making Machine

Video

Well-run tools, skilled gross sales team, and improved after-sales companies; We're also a unified huge family members, absolutely everyone stick to the organization benefit "unification, devotion, tolerance" for Plastic HDPE PE PP MPP Electricity Conduit Water Supply Hose Pipe Tube Extruder Making Machine, We have been searching forwards to creating long-term business interactions with worldwide customers.

Well-run tools, skilled gross sales team, and improved after-sales companies; We're also a unified huge family members, absolutely everyone stick to the organization benefit "unification, devotion, tolerance" for Double Three Layers Sewage HDPE PP MPP GAS PE Double Cavity Coil Pipe Extrusion Productio Line, Our business activities and processes are engineered to make sure our customers have access to widest range of products and solutions with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have now people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

| Model | Screw Diameter(mm) | L/D ratio | Main motor power(kw) |

| SJ65/33 | 65 | 33 | 45/75/90 |

| SJ75/33 | 75 | 33 | 110/132 |

| SJ90/33 | 90 | 33 | 160/185 |

| SJ120/33 | 120 | 33 | 280/315 |

| SJ150/33 | 150 | 33 | 355/400 |

| SJ50/38 | 50 | 38 | 75 |

| SJ60/38 | 65 | 38 | 110 |

| SJ75/38 | 75 | 38 | 160 |

| SJ90/38 | 90 | 38 | 250/280 |

Technical parameter:

| NO. | Name | Quantity |

| 1 | Single screw extruder (with automatic feeding system) | 1set |

| 2 | Mould | 1set |

| 3 | Vacuum calibrating tank | 1set |

| 4 | Water cooling tank | 1set |

| 5 | Haul-off machine | 1set |

| 6 | Cutting machine | 1set |

| 7 | Bracket | 1set |

Details Images

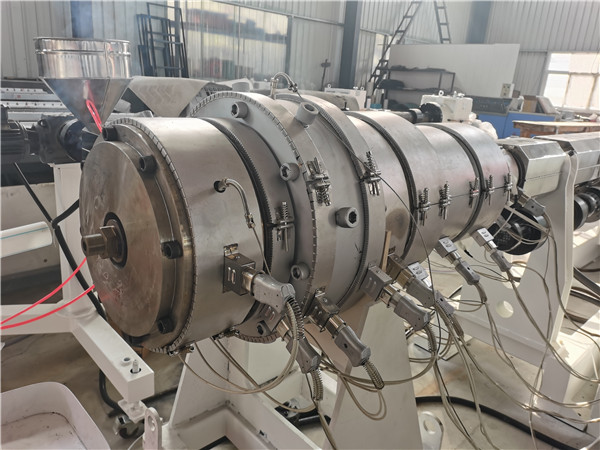

1. HDPE PE pipe extrusion line making machine:Single screw extruder

(with automatic feeding system)

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider (6) Heating method: Cast aluminum heating

(7) Material of screw and barrel: 38CrMoAlA.

2.HDPE PE pipe extrusion line making machine:Mold

(1) Material: 40GR

(2) Size: Customized

3.HDPE PE pipe extrusion line making machine:Vacuum calibrating tank

(1) Vacuum pump power : 5.5 kw

(2) Material: Stainless steel

(3) Diameter: Customized

(4) Length: 6 m

4.HDPE PE pipe extrusion line making machine:Water cooling tank

(1) Water pump power: 4 kw

(2) Material: Stainless steel

(3) Method: Enforced spraying

(4) Length of tank: 6 m

5.HDPE PE pipe extrusion line making machine:Haul-off machine

(1) Driving motor power: 2.2 kw

(2) Transducer: Siemens transducer

(3) hauling track type:110 plastic block

(4) Pressing method: Pneumatic pressing

(5) Effective clamping length:1800 mm

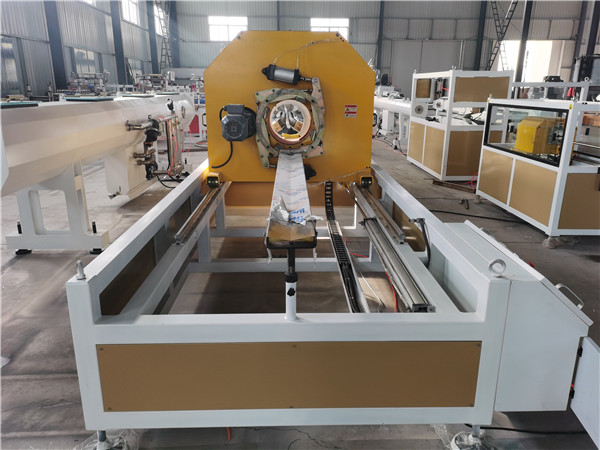

6.HDPE PE pipe extrusion line making machine:Cutting machine

(1) Motor power: 3 kw

(2) Method: Saw cutting

(3) Cutting scope: Customized

(4) PLC control system, using meter counter or sensor switch for the setting of desired length.

7.HDPE PE pipe extrusion Line making machine:Bracket

(1) Length: 6 m

(2) Material: Stainless steel

(3) Unloading method: Pneumatic unloading

Final product:

Well-run tools, skilled gross sales team, and improved after-sales companies; We're also a unified huge family members, absolutely everyone stick to the organization benefit "unification, devotion, tolerance" for Professional Design PE HDPE Mpp PVC Electric Corrugated Pipe Production Line, We have been searching forwards to creating long-term business interactions with worldwide customers.

Professional Design China PE Corrugated Pipe Production Line and PVC Corrugated Pipe Extruder, Our business activities and processes are engineered to make sure our customers have access to widest range of products and solutions with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have now people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

After-sale service

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).