China wholesale Plastic Pipe Extrusion Machine Factory – PVC Corrugated Pipe Making Machine – Tracy

China wholesale Plastic Pipe Extrusion Machine Factory – PVC Corrugated Pipe Making Machine – Tracy Detail:

| Model | Pipe Diameter(mm) | Production Speed(m/min) | Production Capacity(kg/h) | Total Power(kw) |

| SJ30/33 | 6~10 | 10~12 | 20 | 12 |

| SJ45/33 | 10~32 | 6~8 | 40 | 20 |

| SJ45/33 | 25~50 | 6~8 | 70 | 30 |

| SJ55/33 | 25-63 | 5-6 | 80 | 45 |

| SJ65/33 | 25-110 | 4-5 | 120 | 60 |

| SJ75/33 | 50~160 | 3-6 | 150 | 70 |

Technical parameter:

| NO. | Name | Quantity |

| 1 | Single screw extruder with automatic loading device | 1set |

| 2 | Mould | 1set |

| 3 | Corrugated forming machine | 1set |

| 4 | Chipless cutting machine | 1set |

| 5 | Two stations winding machine | 1set |

| 6 | Perforator | 1set |

Details Images

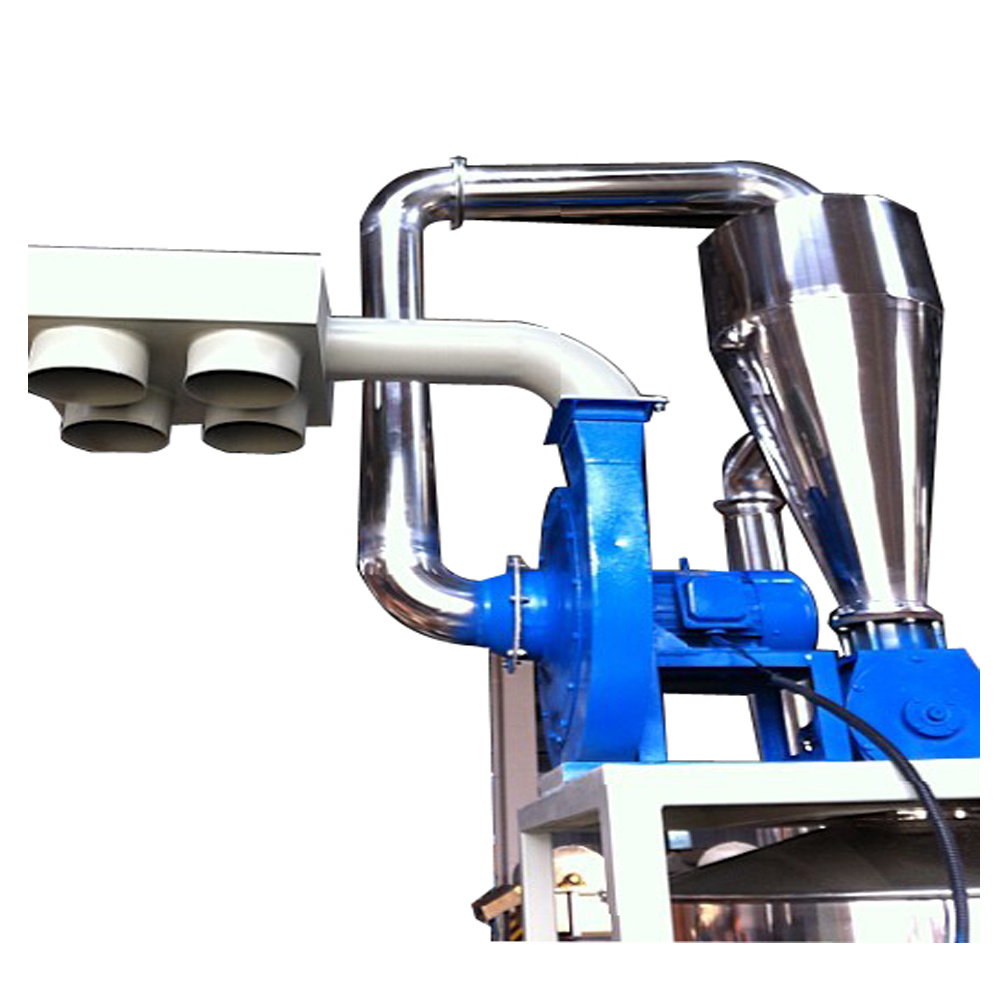

1.PVC corrugated pipe making machine:Single screw extruder

(with automatic feeding system)

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider (6) Heating method: Cast aluminum heating

(7) Material of screw and barrel: 38CrMoAlA.

2.PVC corrugated pipe making machine:Mold

The mould is made of high-quality alloy steel, the internal flow channel is chrome-plated and highly polished, which is wear-resistant and corrosion-resistant; With the special sizing sleeve, the product production speed is hight and the surface of the pipe is good.

(1) Material: 40GR

(2) Size: Customized

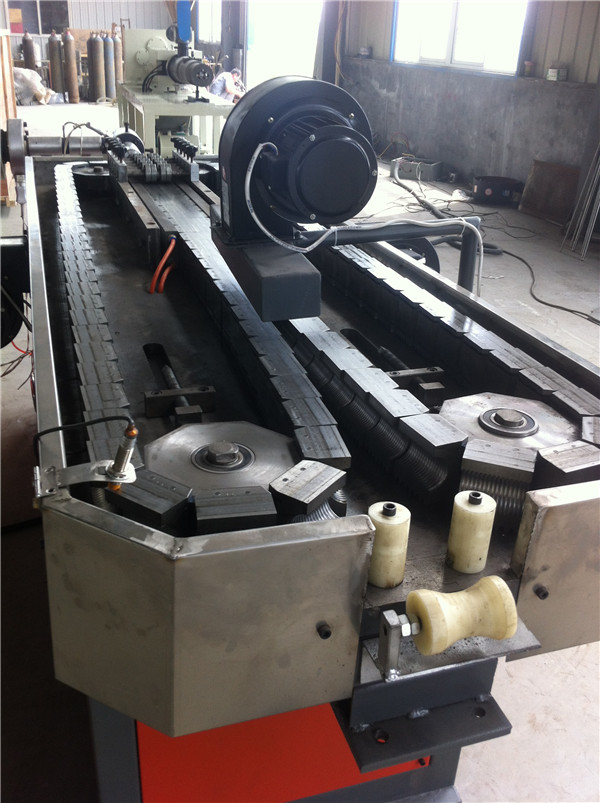

3.PVC corrugated pipe making machine:Forming machine

The corrugated formig device can calibrate and cool the pipe from the mould.

(1) Structure Horizontal.

(2) Guide track material is 40Cr.

(3) Block seat material is 40Cr, nitrided.

(4) AC motor: 2.2KW x 1 set.

(5) Blocks is cooled by air cooling fan.

4.PVC corrugated pipe making machine:Cutting machine

(1) Motor power: 3 kw

(2) Method: Saw cutting

(3) Cutting scope: Customized

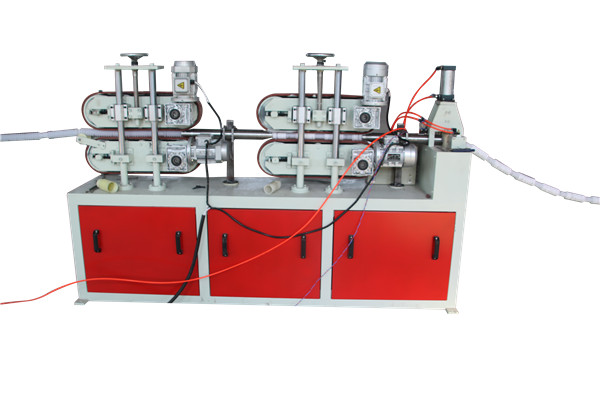

5.PVC corrugated pipe making machine:Two stations winding machine

(1) Two stations automatic winding unit without stopping.

(2) Torque Motor:4-6N/M or customizable.

Final product:

Video

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer’s factory.

3.Delivery time: 20~30 days.

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for China wholesale Plastic Pipe Extrusion Machine Factory – PVC Corrugated Pipe Making Machine – Tracy, The product will supply to all over the world, such as: Islamabad, Sri Lanka, Bangladesh, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.