-

40-160mm MPP Pipe Electric Tube Siemens Motor Plastic Single Screw Extruder Machine Production Line

The HDPE plastic pipe extrusion line making machine can be used for different diameter HDPE PE Pipe production which have excellent stiffness and flexibility, heat resistance, aging resistance, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage, and so on. So, this pipe production line is a preferred for ductwork system of gas, water pipe and agricultural irrigation pipe between city and village.

You just tell me what machine you want,let us do the rest work:

1. Design and manufacture suitble machine for you.

2. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)

3. Delivery.

4. We will provide after-sales service:

(1) Field installation and commissioning;

(2) Field training your workers;

(3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.

-

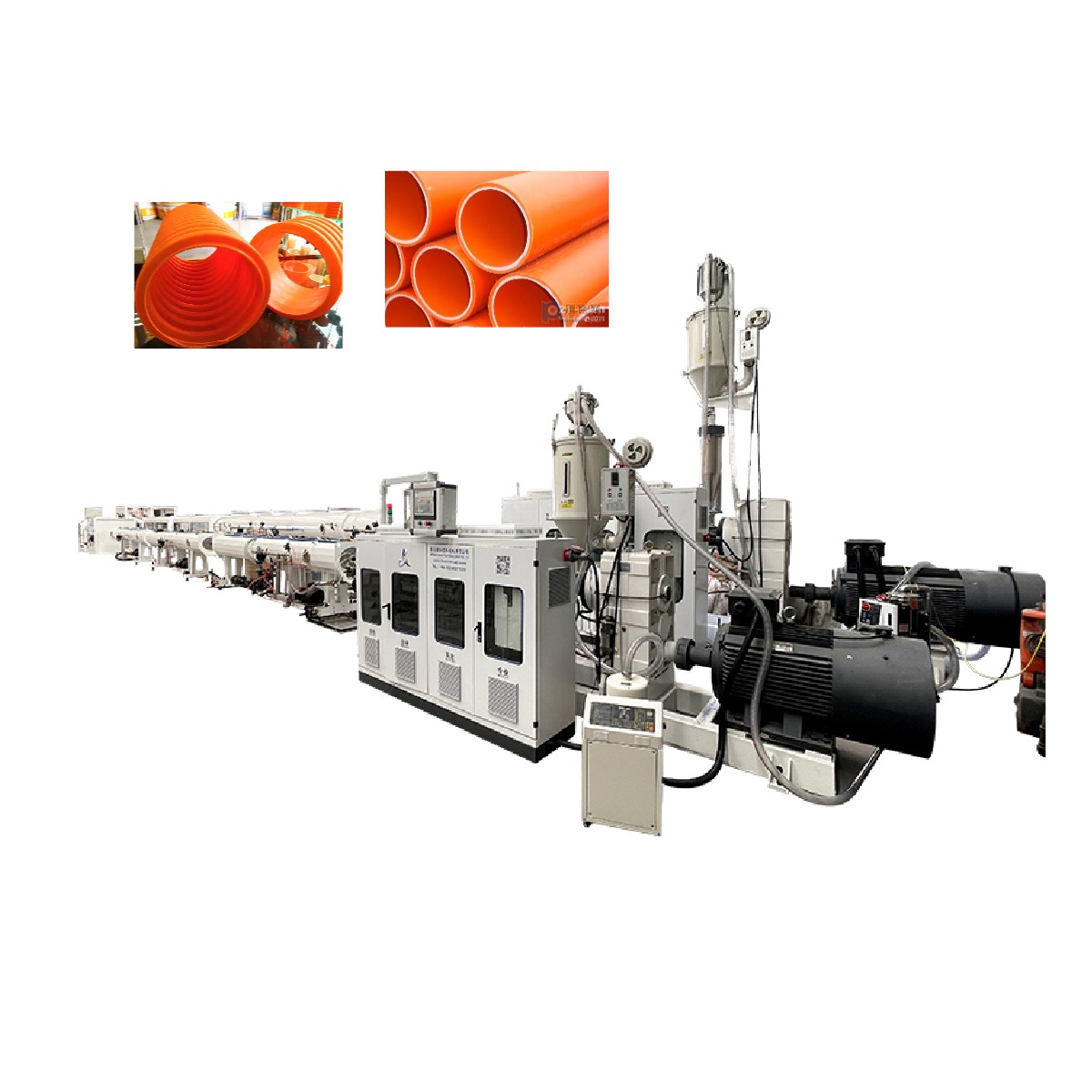

High Pressure MPP Pipe 75-250mm MPP Corrugated Pipe Orange Tube Making Machine Production Line

The HDPE plastic pipe extrusion line making machine can be used for different diameter HDPE PE Pipe production which have excellent stiffness and flexibility, heat resistance, aging resistance, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage, and so on. So, this pipe production line is a preferred for ductwork system of gas, water pipe and agricultural irrigation pipe between city and village.

You just tell me what machine you want,let us do the rest work:

1. Design and manufacture suitble machine for you.

2. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)

3. Delivery.

4. We will provide after-sales service:

(1) Field installation and commissioning;

(2) Field training your workers;

(3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.