China wholesale Wpc Pvc Foam Board Making Machine Factories – China New WPC PVC Spc Artificial Marble Stone Floor Board Machinery with UV Coating Extrusion Line – Tracy

China wholesale Wpc Pvc Foam Board Making Machine Factories – China New WPC PVC Spc Artificial Marble Stone Floor Board Machinery with UV Coating Extrusion Line – Tracy Detail:

We consistently execute our spirit of ”Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for China New WPC PVC Spc Artificial Marble Stone Floor Board Machinery with UV Coating Extrusion Line, We consider in top quality more than quantity. Before export in the hair there is strict quality control check during treatment as per international excellent standards.

We consistently execute our spirit of ”Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for China Plastic Machine, Extrusion, Our company has always insisted on the business principle of “Quality, Honest, and Customer First” by which we have now won the trust of clients both from at home and abroad. If you are interested in our products and solutions, be sure to do not hesitate to contact us for further information.

Specifications:

| Model | Products Width (mm) | Products Thickness(mm) | Production Capacity (kg/h) | Total Power(kw/h) |

| SJSZ80/156 | 800~1600 | 0.3~3 | 300~450 | 160 |

Technical parameter

| NO. | Specification | Quantity |

| 1 | Automatic loading system | 1set |

| 2 | SJSZ80/156 conical double screw extruder | 1set |

| 3 | Mould | 1set |

| 4 | Three roll calender with temperature controller | 1set |

| 5 | Laminating device | 1set |

| 7 | Edge cutting unit | 1set |

| 8 | Hual off machine | 1set |

| 9 | Cutting machine | 1set |

| 10 | Auto stacker | 1set |

Details Images

1.PVC Artificial Sheet Making Machine:

SJSZ80/156 conical double screw extruder with automatic loading system

(1)Big output & L/D ratio screw

(2)Barrel is made of special steel alloy.

(3)Gears are made of steel alloy with heat treatment and are finished with surface precision grinding.

(4)AC motor, selected famous brand products.

(5)Controlled by ABB Inverter.

2.PVC Artificial Sheet Making Machine: Mold

(1)Coated with chrome & polished

(2)Alloyed mould steel material

(3)Heating rod

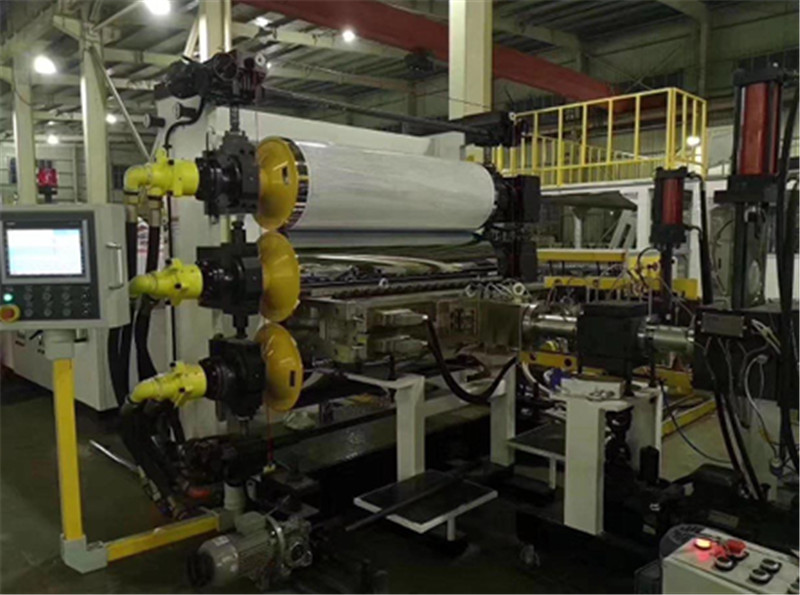

3.PVC Artificial Sheet Making Machine:

Three roller Calender and side winder with laminating equipemt

(1)With emergency stop Adjusting method the roller space

(2)neumatic adjusting Temp-regulating of roller

(3)water-heating and cooling Blade method side cutting Electric part with CE certificate Temperature control system

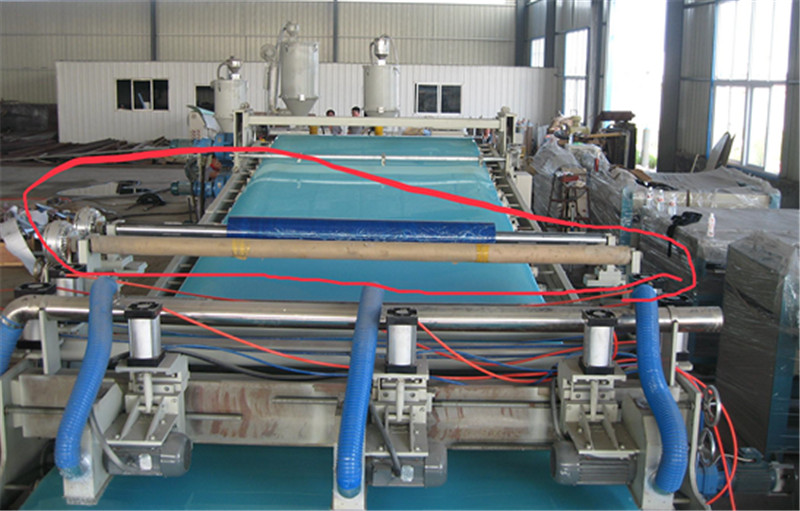

4.PVC Artificial Sheet Making Machine:

Bracket and Haul-off Machine

(1)A pair of rubber rollers haul off

(2)Speed adjustable control, the up and down rollers are synchronized via drive unit.

(3)With emergency stop

5.PVC Artificial Sheet Making Machine:

Cutting machine

(1) With Digital Meters, automatic control cutting length.

(2) Pneumatic system

(3) Push cylinder

(4)Knife

6.PVC Artificial Sheet Making Machine:

Final product bracket with robot hands

(1) Material stainless steel

(2) Dimension 2500*1300*1000mm

Final Product:

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for China wholesale Wpc Pvc Foam Board Making Machine Factories – China New WPC PVC Spc Artificial Marble Stone Floor Board Machinery with UV Coating Extrusion Line – Tracy, The product will supply to all over the world, such as: Philadelphia, Naples, Turkmenistan, Should any of these items be of interest to you, please let us know. We'll be satisfied to give you a quotation upon receipt of one's detailed specifications. We have our personal experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!