Pet Sheet Production Line - Plastic PP PC PVC Corrugated Roofing Tile Sheet Extrusion Line Plastic PP PET Sunroom Roof Tile Production Line – Tracy

Pet Sheet Production Line - Plastic PP PC PVC Corrugated Roofing Tile Sheet Extrusion Line Plastic PP PET Sunroom Roof Tile Production Line – Tracy Detail:

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for Plastic PP PC PVC Corrugated Roofing Tile Sheet Extrusion Line Plastic PP PET Sunroom Roof Tile Production Line, We consider excellent as the foundation of our results. Thus, we focus on the manufacture of your best high quality items. A strict excellent management system has been created to make sure the standard of the items.

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for China Tile Making Machine and Glazed Tile Machine, High Quality PVC UPVC PC Corrugated Glazed Tile Roof Forming Sheet, Making Machine Extrusion Line, We believe in quality and customer satisfaction achieved by a team of highly dedicated individuals. The team of our company with the use of cutting-edge technologies delivers impeccable quality products and solutions supremely adored and appreciated by our customers worldwide.

| NO. | Specification | Quantity |

| 1 | Double screw extruder with Automatic loading system | 1 set |

| 2 | Mould | 1 set |

| 3 | Forming machine bracket | 1 set |

| 4 | Haul off machine | 1 set |

| 5 | Cutting machine | 1 set |

| 6 | Stacker | 1 set |

Technical parameter:

|

Model |

Production width (mm) |

Capacity(kg/h) |

Total Power(kw/h) |

| SJZ80/156 |

1000 |

300 |

100 |

Details Images

1.PVC Corrugated hollow sheet making machine :

Double screw extruder(with automatic feeding system)

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider (6) Heating method: Cast aluminum heating

(7) Material of screw and barrel: 38CrMoAlA.

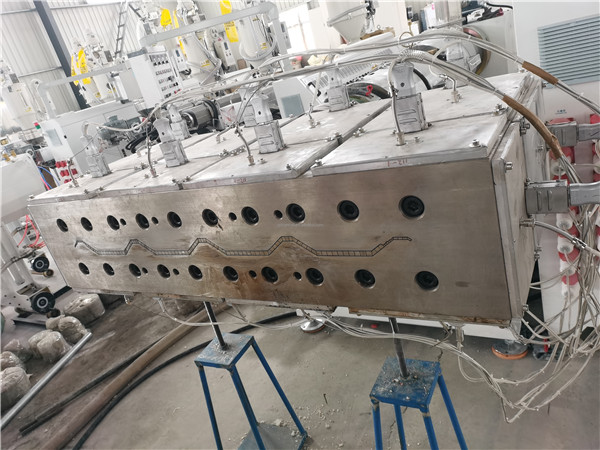

2.PVC Corrugated hollow sheet making machine: Mold

(1) Material: 40GR

(2) Size: Customized

3.PVC Corrugated hollow sheet making machine :Forming machine

(1) Stainless steel clamping platform

(2) Material: Stainless steel

(3) Diameter: Customized

4.PVC Corrugated hollow sheet making machine :Haul-off machine

(1) Driving motor power: 11 kw

(2) Drawing speed: 0.2~5 m/min

(3) Haul-off method: 6 caterpillars

5.PVC Corrugated hollow sheet making machine :cutting machine

(1) Method: Saw cutting

(2) Cutting scope: Customized

(3)Power :3KW

6.PVC Corrugated hollow sheet making machine Stacker

1) Length:6 m

(2) Width:1m

(3) Material: Stainless steel

Final product:

Video

Product detail pictures:

Related Product Guide:

Sticking to the principle of "Super Quality, Satisfactory service" ,We are striving to be a good business partner of you for Pet Sheet Production Line - Plastic PP PC PVC Corrugated Roofing Tile Sheet Extrusion Line Plastic PP PET Sunroom Roof Tile Production Line – Tracy, The product will supply to all over the world, such as: Hungary, Armenia, Malta, The president and all the company members would like to provide qualified goods and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.