2 Layers PET Sheet Plastic Extruder Machine PET Thermoforming Sheet Machine 100% Recycle Machine Production Line

We’re experienced manufacturer. Wining the majority in the crucial certifications of its market for 2 Layers PET Sheet Plastic Extruder Machine PET Thermoforming Sheet Machine 100% Recycle Machine Production Line, We welcome buyers everywhere in the word to get in touch with us for future business enterprise interactions. Our merchandise are the most effective. Once Selected, Ideal Forever!

We’re experienced manufacturer. Wining the majority in the crucial certifications of its market for 3 Layers Film Fully Automatic PET Sheet Plastic Making Machinery Production Line, Automatic PET Sheet Extrusion Making Machine, PET Transparent Film Extrusion Line, Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

The whole production line consists of the following six parts:

| NO. | Name | Quantity |

| 1 | Twin screw extruder | 1 set |

| 2 | Die head | 1 set |

| 3 | Three roller calendar | 1 set |

| 4 | Heat exchanger units | 1 set |

| 5 | Edge cutting unit and cooling bracket | 1 set |

| 6 | Haul-off machine | 1 set |

| 7 | Winding machine | 1 set |

Technical parameter:

| Type | Model | Thickness(mm) | Power(kw) | Capacity(kg/h) |

| Multi-layer | 120/65-1000 | 0.2—1.5 | 110/45 | 500 |

| Single layer | 120-1000 | 0.2—1.5 | 110 | 450 |

| Highly efficient | 150-1500 | 0.2—1.5 | 160 | 800 |

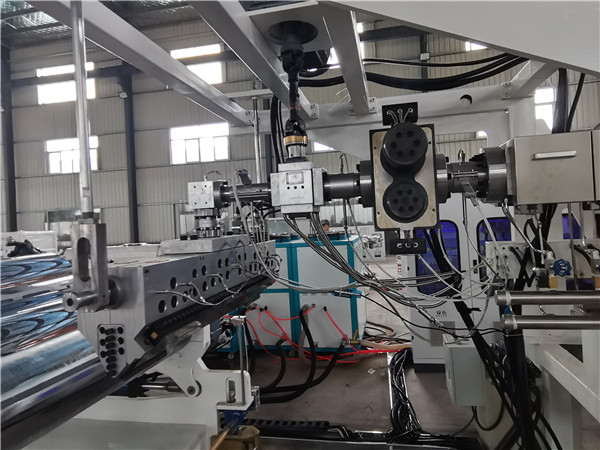

Details Images

1.Twin screw extruder

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider

(6) Heating method: Ceramic or cast alumin

(7) Mater screw and barrel: 38CrMoAlA

2. Die head

(1) Width of mould : 1250mm or customized

(2) Finished product thickness: 0.2-2 mm

(3) Material: Alloyed mold steel

3. Three roller calendar

(1) Roller length: 1300mm

(2) Max. Roller diameter: Ø400mm

(3) Line speed: 2.2 m/min

4. Edge cutting unit and cooling bracket and haul-off machine

(1) Cooling bracket length: 6m

(2) Diameter of sloe-cooling roller: Ø70mm

(3) Length of sloe-cooling roller: 1300mm

(4) Diameter of haul-off roller: Ø160mm

(5) Length of haul-off roller: 600mm

(6) Haul-off line speed: 1.5-15 m/min

5. PET sheet winding machine machine